CASE STUDIES

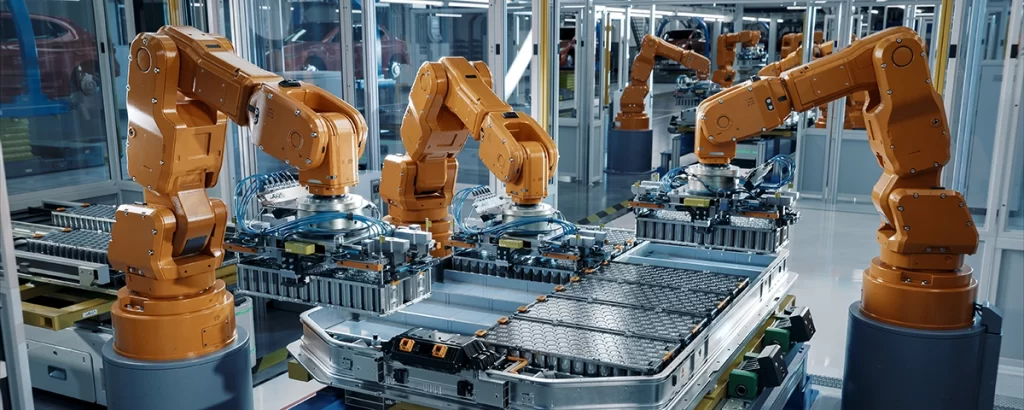

Micro data centres for manufacturing

Smart data storage solutions for the manufacturing industry

Smart manufacturing

In the dynamic field of manufacturing, technology plays a crucial role in transforming how we produce and manage products. Smart manufacturing leverages advanced digital tools and edge computing to optimise production processes, enhance operational efficiency, and improve product quality.

Manufacturing facilities are often complex and geographically dispersed, making edge computing vital for maintaining seamless connectivity and efficient data processing.

However, integrating edge computing into manufacturing environments presents unique challenges:

- Limited connectivity

- Data security

- Harsh industrial environments

- Scalability

Addressing the challenges of the manufacturing industry with smart, edge-ready solutions

Our products have been designed to address the critical challenges of edge computing, even in diverse and dynamic manufacturing environments. Here are six ways micro data centres solve manufacturing industry challenges:

Enhanced connectivity

Micro data centres ensure consistent and reliable connectivity, even in remote or underserved areas, enabling uninterrupted access to digital manufacturing resources.

Data security

They provide robust security measures, including encryption and secure access controls, to protect sensitive production and operational data.

Scalability

Micro data centres can be easily scaled to meet the growing demands of manufacturing facilities, accommodating increasing data and connectivity needs.

Resilience

Built to withstand various environmental conditions, micro data centres ensure continuous operation and data integrity, even in challenging industrial settings.

Cost efficiency

By decentralising data processing and storage, micro data centres reduce the need for expensive, centralised infrastructure.

Network performance

With localised data processing, micro data centres support real-time analytics and tailored production processes, improving overall efficiency and product quality.

Manufacturing case studies

Kenmore Group

The Kenmore Group wanted to standardise their data centres with a view to lower energy bills. Find out how we helped reduce costs.

Edge-ready micro data centres

Our cutting-edge range of micro data centres and containerised data centres is designed to meet the demands of today’s rapidly evolving telecom landscape.

Engineered for agility, scalability, standardisation, and efficiency, our solutions empower telecom providers to deploy robust infrastructure at the edge, ensuring seamless operations and unparalleled performance in any network environment.